Health monitoring of steel structures: from inspections to insights

Continuous insight into structural integrity

For many operators, one of the hardest maintenance decisions is knowing when to act. Replace too late and you risk safety. Replace too early and you lose valuable time, materials, and money.

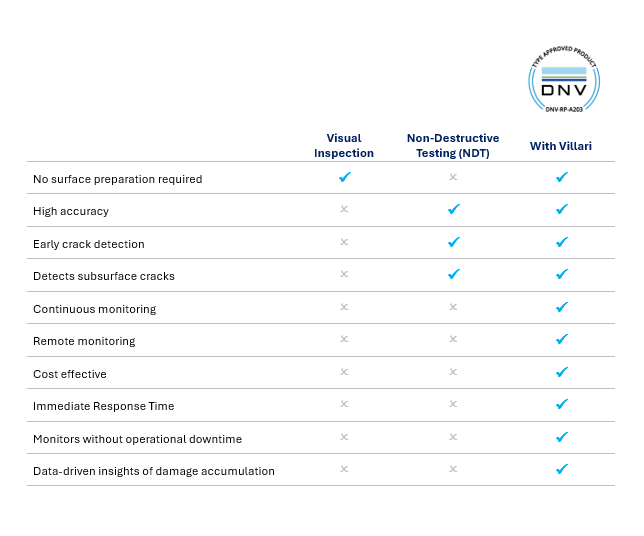

Traditionally, structural integrity checks rely on manual inspections, which are time-consuming, costly, and limited to snapshots in time. But what if you could see what’s really happening inside your steel structures every day, in real time?

That’s the promise of our health monitoring service for steel structures, now offered by Control Union in partnership with Villari.

Why traditional inspections fall short

Every steel structure, from cranes to bridges to heavy lifting frames, is subject to fatigue. Over time, repeated loads cause tiny cracks to form. Detecting them early is critical, but conventional inspections depend on physical access and specialised equipment. These inspections can take hours, require scaffolding or rope access, and often cause operational downtime.

The solution: continuous monitoring

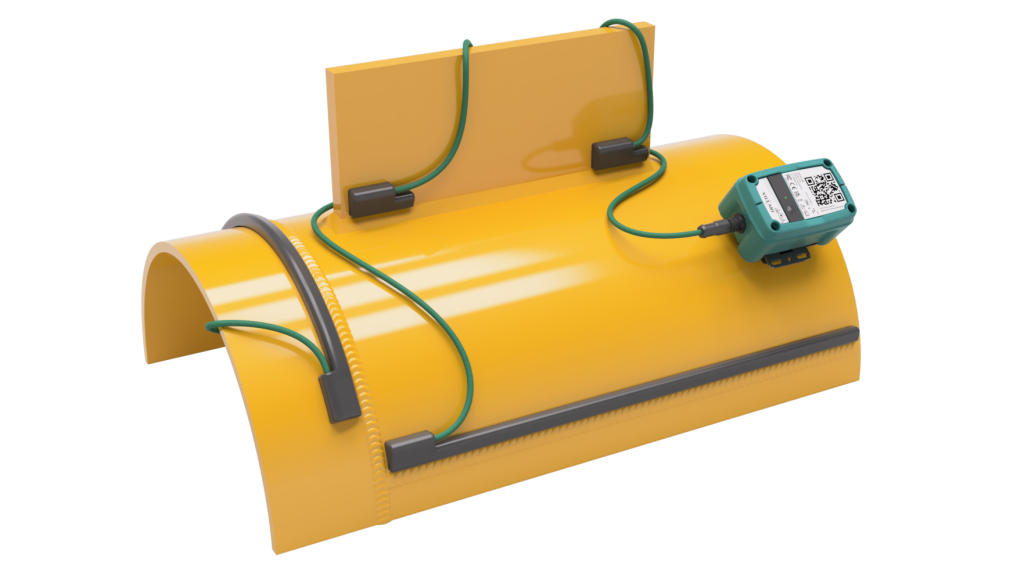

The system itself is remarkably straightforward.

Each wireless transmitter connects to rigid or flexible sensor probes that are bonded to the steel surface using a durable industrial adhesive, typically near welds or other critical areas where fatigue cracks are most likely to occur.

Depending on your needs and use cases, you may decide to install the probes either for preventive or reactive reasons.

- Preventive placement focuses on monitoring critical locations identified through fatigue analysis, providing early warnings before cracks initiate.

- Reactive placement, on the other hand, allows targeted monitoring of known or repaired cracks to confirm that no further propagation occurs.

This flexibility makes the system suitable for both new and existing structures, across a wide range of industrial applications.

The transmitter, which collects and transmits the data, can be mounted using a high-strength industrial magnet or attached with a bracket, depending on the environment, accessibility, or specific project requirements. This flexible installation design ensures quick, secure deployment across a wide range of industrial applications.

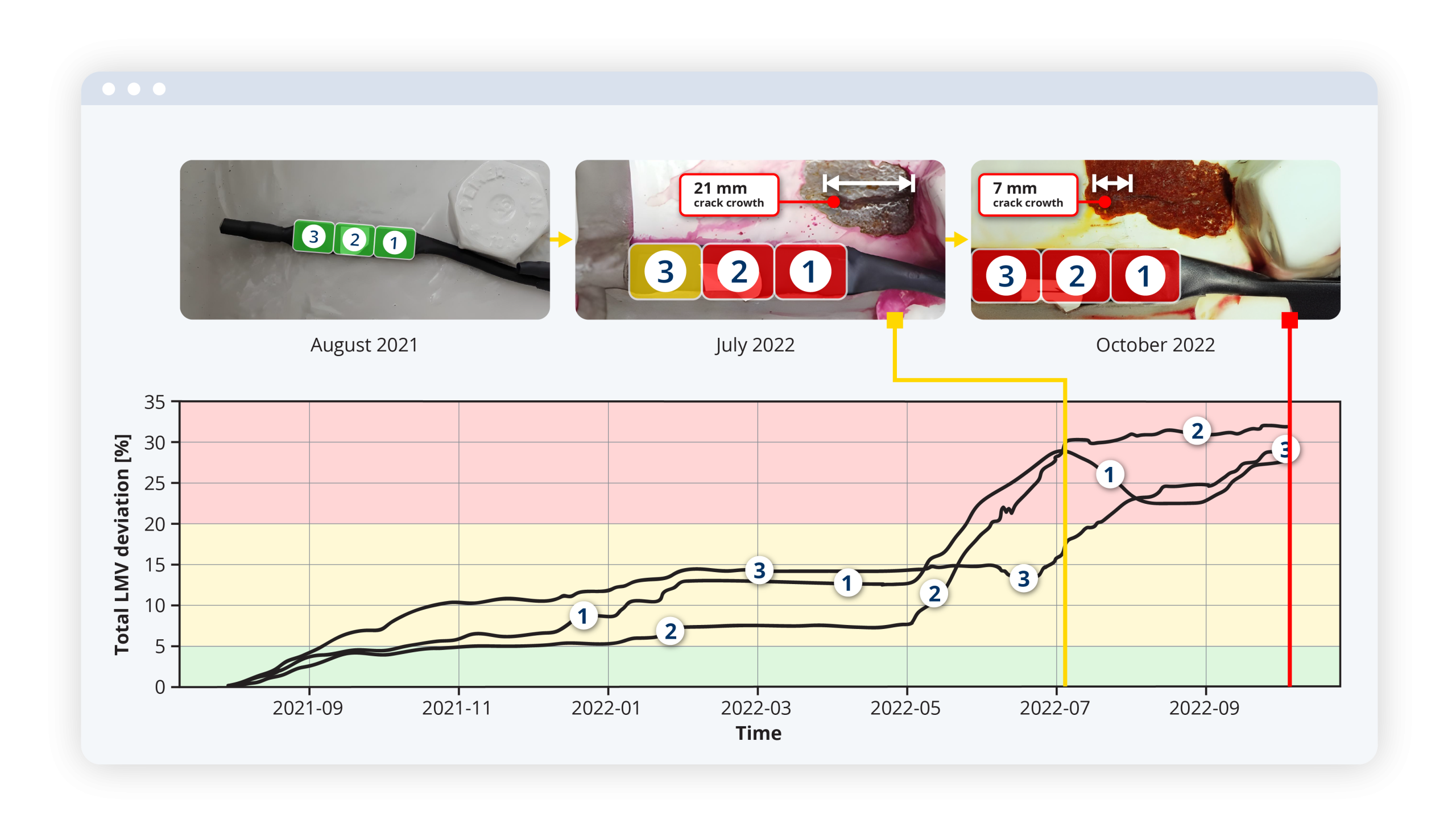

Once installed, the sensors quietly do their job, collecting data around the clock and sending it wirelessly via the low-power LoRaWAN network to the digital dashboard, which helps extend the sensors’ battery life. The system continuously measures minute changes in the magnetic field, allowing it to identify the first signs of stress or crack growth before damage becomes visible.

The Villari system

The Villari system, a type approved wireless sensor system for steel structures, replaces the calendar-based approach of traditional inspections with continuous, real-time monitoring. Data are securely transmitted via LoRaWAN network and visualised in an online dashboard using an intuitive traffic-light interface. Green means all is well, yellow signals attention, and red calls for action.

Built for demanding environments

Beyond its simplicity, the Villari system is engineered to perform in even the harshest operational conditions. Its key characteristics include:

- DNV-RP-A203 type approved product

- LoRaWAN wireless module for secure, long-range data transmission

- IP66 housing, UV-resistant and built for heavy-duty industrial use

- Operates reliably from –40°C to +80°C

- Supports up to 20 probes per unit

- 5-year battery life

- Globally deployable

Real stories, real savings

One terminal operator faced recurring fatigue cracks in two large ship-to-shore cranes. Routine inspections were costing around $15,000 per crane each year and caused frequent downtime. By installing 32 sensor probes, each crane was back in operation within two hours, and annual inspection costs dropped by 30%.

Another case involved an aging crane that had already exceeded its design life. Traditional analysis required three inspections per year to maintain safety. Instead, 200 sensors were installed to continuously monitor the structure, allowing safe operation for an additional six years at one-third the cost of traditional inspections.

Even in the steel industry, where production interruptions are costly, Villari’s technology made a measurable impact. On a 400-ton ladle crane, the sensors revealed slow, consistent crack growth, allowing the operator to safely postpone $30,000 in repairs for four years.

Across industries, integrating continuous monitoring into existing inspection schedules has proven to reduce inspection frequency, cost, and downtime, while maintaining full compliance and safety standards. Instead of replacing inspections, it makes them smarter, more targeted, and far less intrusive.

Type approved innovation

This isn’t experimental technology; it’s proven and DNV type approved under DNV-RP-A203. Each sensor continuously monitors its surrounding area, detecting potential crack growth before it becomes visible. The system provides thousands of data points daily, giving operators unprecedented visibility into their structures’ condition.

By integrating this type approved system into our inspection and asset-integrity services, Control Union enables a proactive, data-driven approach to maintenance that is safer, smarter, and more sustainable.

Once integrated into existing inspection regimes, the system can significantly reduce inspection frequency and associated costs, without compromising on safety or compliance.

Sustainability and peace of mind

For Control Union, sustainability is not only about reducing environmental impact but also about managing existing assets responsibly. Every structure that remains safely in service for longer is one less replacement, saving materials, energy, and cost.

Reliable data removes uncertainty from maintenance planning. You no longer need to choose between caution and confidence. You can act precisely when needed, not before and not after when it’s already too late.

Contact us to learn how data-informed maintenance can support your safety and sustainability goals.

How can we help you?

Can we help you with more specific information about our services? Or maybe some advice in your own language? Or do you need a quotation? Let us know and we will gladly help.