Health monitoring of steel structures

At Control Union, we continuously look for innovative ways to support our clients in maintaining safe and reliable operations. Our health monitoring service for steel structures provides continuous insight into the condition of critical steel assets, helping to detect early signs of stress, fatigue, or cracking before they lead to costly downtime.

Real-time monitoring for smarter steel maintenance

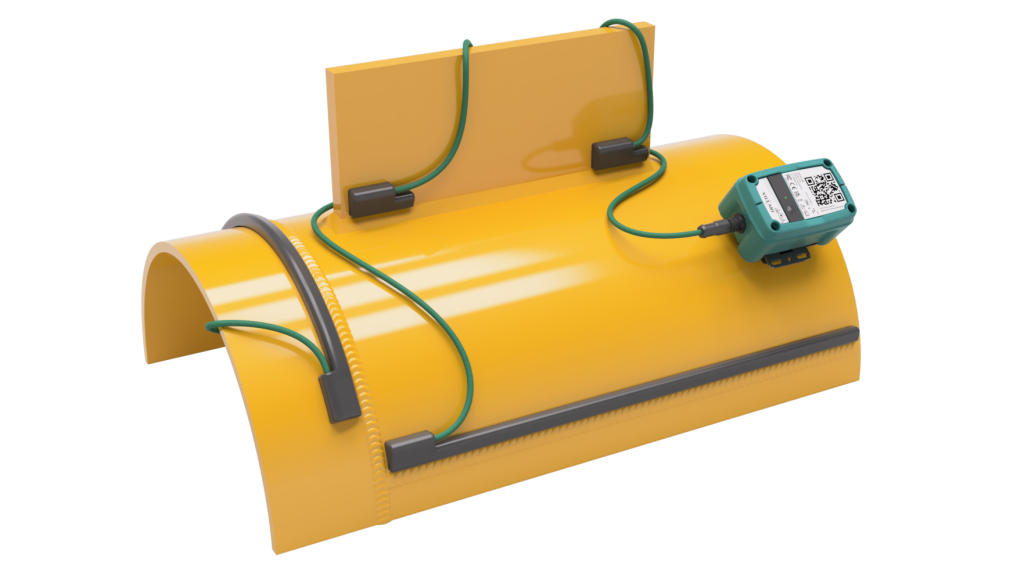

By delivering and installing permanently mounted, wireless sensors, we enable remote, real-time monitoring of ferritic steel structures. This allows our clients to move from scheduled inspections to a data-driven and condition-based maintenance strategy that improves safety, extends asset lifetime, and reduces overall maintenance costs.

By integrating this system into existing inspection regimes, operators can significantly reduce inspection frequency and associated costs, while maintaining full compliance with safety standards. The result is a more efficient and predictable maintenance process that minimises downtime and overall lifecycle cost.

Developed by Villari, a leading innovator in smart sensing technology, this wireless sensor system is offered in partnership with Control Union and combines proven magnetic sensing with advanced analytics. All collected data are visualised through a secure online portal, providing clear and actionable information on structural performance and degradation trends.

With this service, Control Union enhances its commitment to innovation, safety, and asset integrity. Our health monitoring solution supports industries that rely on critical steel structures, offering confidence, efficiency, and long-term operational insight.

Type Approved Technology

The Villari system sets a new standard in wireless crack detection for steel structures. This DNV type approved solution detects early-stage crack growth and measures crack propagation in steel by monitoring passive magnetic flux leakage and plastic deformation (the “Villari effect”).

Each probe continuously records changes in the magnetic field, allowing early identification of potential fatigue cracks. The collected data are securely transmitted via the LoRaWAN network and visualised in a digital dashboard that clearly indicates the structural condition through an intuitive traffic-light interface. This provides reliable, real-time insight into the presence (or absence) of crack growth in the areas identified as most critical or most likely exposed to fatigue.

By integrating this type approved technology into our inspection services, Control Union offers clients a proven and practical solution for predictive maintenance that reduces inspection complexity while strengthening safety and long-term asset performance.

Sustainability

We believe that sustainability is not only about reducing environmental impact, but also about making smarter use of existing assets. Every unnecessary replacement has a cost, not just financially, but in material waste and energy consumption.

Our health monitoring service for steel structures helps clients to make informed decisions about maintenance and replacement. By providing reliable, real-time data on the actual condition of steel structures, it removes uncertainty from the decision-making process.

Too often, equipment is replaced early simply to stay on the safe side. With continuous insight into structural performance, you no longer have to choose between caution and confidence. You can act when it is truly necessary, extending the lifespan of your assets while maintaining full assurance of safety and integrity.

This is what sustainability means to us: using data and insight to balance safety, responsibility, and long-term value.

Contact us to learn how data-informed maintenance can support your safety and sustainability goals.

How can we help you?

Can we help you with more specific information about our services? Or maybe some advice in your own language? Or do you need a quotation? Let us know and we will gladly help.